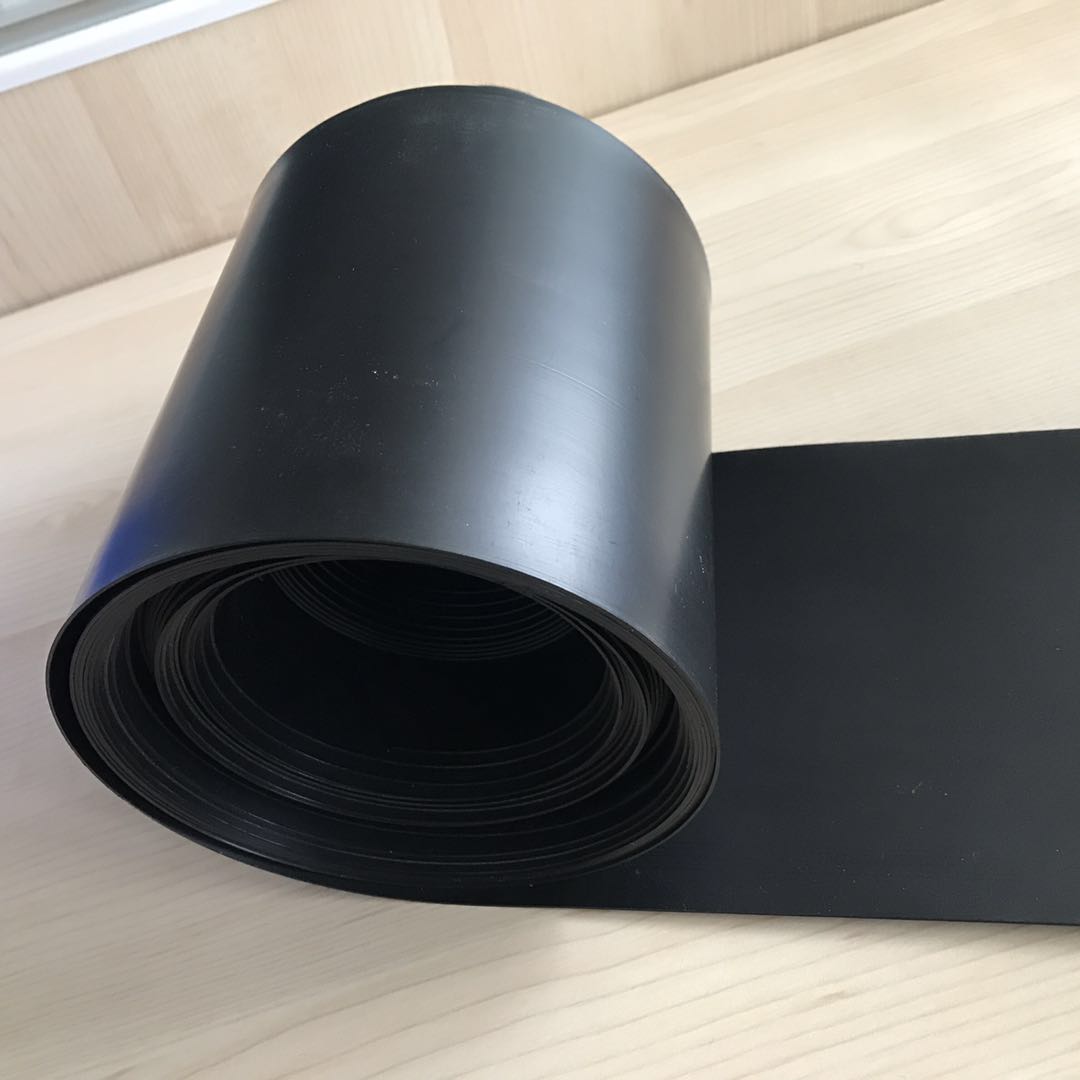

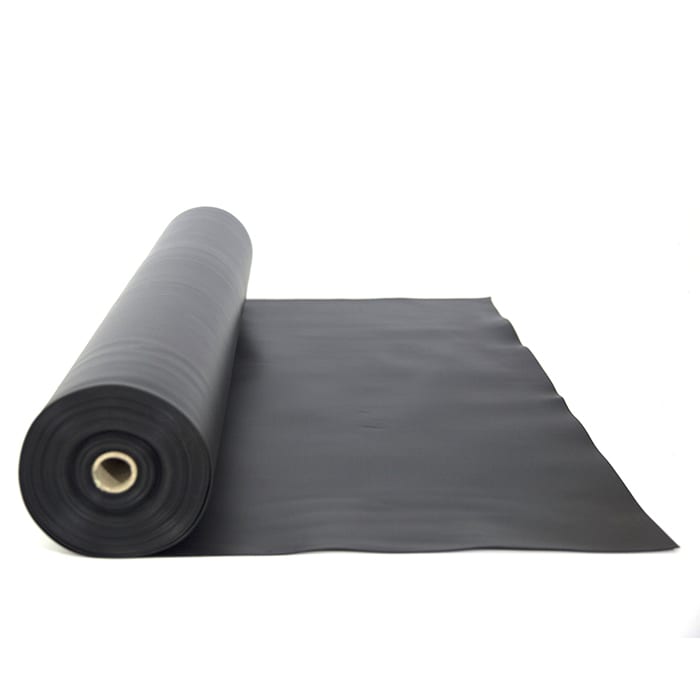

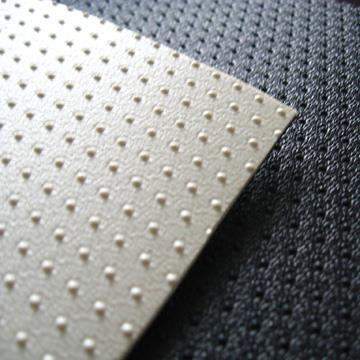

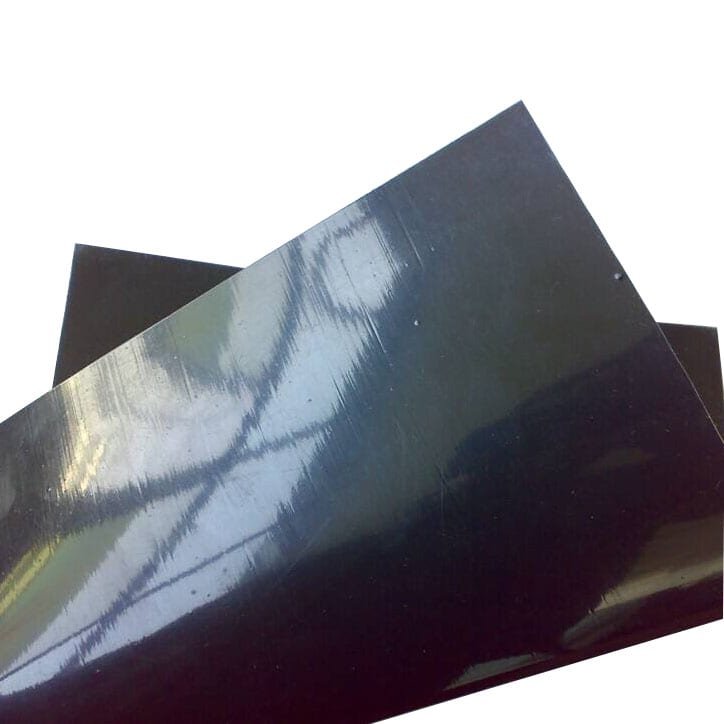

HDPE geomembrane ( high density polyethylene geomembrane) use high-quality polyethylene virgin resin, the main component of 97.5% of high density polyethylene, about 2.5% of carbon black, anti - aging agent, antioxidant, uv absorber and stabilizer ; Tai'an Taidong introduced ultra width automatic HDPE antiseepage geomembrane production equipment, all products produced according to the GRI standards and ASTM testing standards. We have completed specifications, smooth surface and textured surface, thickness from 0.10 mm to 4.0mm, width can be up to 10 m, the HDPE geomembrane can completely meet the application requirements of Environmental Sanitation, Water Conservancy, Construction, Municipal Engineering, Landscape, Petrochemical, Mining, Salt, Agriculture, Aquaculture.

Product Features: 1.Good physical and mechanic performance. 2.High tearing resistance, strong deformation adaptability. 3.Puncture-resisting, aging resisting, ultra-violet radiation, oil and salt, and corrosion resistance. 4.Good adaptability to high and low temperature, non-toxicity, long service life. 5.Good waterproof, drainage, anti-seepage and damp proof effects. 6.Complete width and thickness specifications, low cost and easy installation. Technical data sheet:| No. | Test item | Technical data | |||||||

| Thickness (mm) | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 | |

| 1 | Density g/m2 | >0.94 | >0.94 | >0.94 | >0.94 | >0.94 | >0.94 | >0.94 | >0.94 |

| 2 | Tensile Yield Strength (MD&TD) (N/mm) | >8 | >11 | >15 | >18 | >22 | >29 | >37 | >44 |

| 3 | Tensile Breaking Strength (MD&TD) (N/mm) | >13 | >20 | >27 | >33 | >40 | >53 | >67 | >80 |

| 4 | Elongation at yield (MD&TD) (%) | >12 | >12 | >12 | >12 | >12 | >12 | >12 | >12 |

| 5 | Elongation at b「eak(MD&TD) (%) | >700 | >700 | >700 | >700 | >700 | >700 | >700 | >700 |

| 6 | Tear Resistance (MD&TD) (N) | >58 | >93 | >125 | >160 | >190 | >250 | >315 | >375 |

| 7 | Puncture Strength (N) | >160 | >240 | >320 | >400 | >480 | >640 | >800 | >960 |

| 8 | Tensile load stress cracking (Constant load tensile method of incision) h | >300 | >300 | >300 | >300 | >300 | >300 | >300 | >300 |

| 9 | Carbon Black Content (%) | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 |

| 10 | 85°C heat aging (Atmospheric OIT retention after 90d) (%) | >55 | >55 | >55 | >55 | >55 | >55 | >55 | >55 |

| 11 | UV protection (OIT retention rate after 1600 h uviolizing) | >50 | >50 | >50 | >50 | >50 | >50 | >50 | >50 |

| 12 | Carbon black dispersion | In 10 datas, Grade 3<1, Grade 4,5 are not allowed | |||||||

| 13 | Oxidative Induction Time (min) | Atmospheric oxidative induction time ≧100 | |||||||

| High pressure oxidative induction time ≧400 | |||||||||